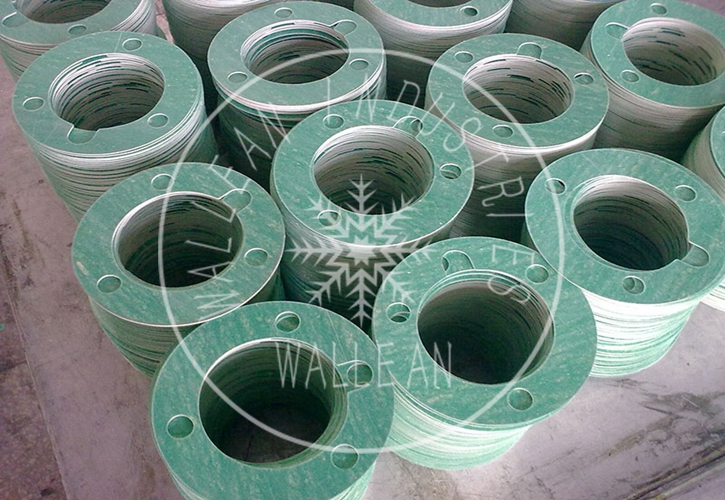

Non-asbestos Gasket£¨CNAF Gasket,Asbestos-free Gasket£©

WL-G1530

Description

Non-asbestos gaskets come in a variety of basic materials comprised of carbon, graphite, fiberglass, aramid fiber, Kevlar and other mineral fibers. The basic components of the non-asbestos materials used in gasket construction are elastomer and filler.Add special adhesives and a little packing into it, then roll and sulfurated. The elastomer composition corresponds to the application of the gasket, assisting in the categorization and selection of the gasket best used for the service it will be performing. It is a replacement of asbestos gasket.

Non-asbestos Gasket has better strength, elasticity.It has supper strong anti-penetrate performance. Non-asbestos Gasket is a better choice than asbestos gasket in high temperature and high pressure condition. And Non-asbestos Gasket is product using material with environment protection.

Typical Properties of Common Elastomers (Rubber Compounds)

NBR - good for oils, gas, mild chemicals and water

SBR - good for saturated Steam, mild chemicals inert gas and water

Neoprene - good for saturated steam, refrigerants, oils, fuels, mild acids and alkalies and water.

EPDM - good for saturated steam, mild chemicals and water

The Process

Gaskets can be cut based on your drawing or sample of the gasket you desire. Basic I.D. x O.D. shapes can be cut by hand however most die cuts gaskets require a die.The size are according to API or DIN standard, also we can produce non-standard as clients' request.

Application

Non-asbestos Gasket are widely used in the industries such as gas, hydrocarbon, solvent, low pressure steam, weak acid and alkali etc.They are applied to some industries of food, mechanical, chemical engineering, petroleum and so on.

Main Specification of Non-asbestos Gasket

|

Pressure |

3.5MPa |

|

Temperature |

=<350¡æ |

|

Lateral Tensile Strength |

8MPa |

|

Compressibility |

12% |

|

Recovery |

=<40% |

|

Stress Relaxation |

=<50% |

|

Size |

OD=<1500mm(special size can be made as request) |

¡¡

Warning: Gasket materials should never be recommended when both the temperature and the pressure are at the maximums listed. Properties and applications shown are typical. No application should be undertaken by anyone without independent study and evaluation for suitability. Never use more than one gasket in one flange joint, and never reuse a gasket. Improper use or gasket selection could cause property damage and/or serious personal injury. The data reported is a compilation of field testing, field service reports and/or in-house testing. While the utmost care has gone into publishing the information contained herein, we assume no responsibility for errors. The information and specifications contained in this website are subject to change without notice. This revision cancels and obsoletes all previous editions.