Spiral Wound Gasket

WL-G1200

Description

Spiral wound gaskets are special semi-metallic gaskets of great resilience, therefore they are very suitable for applications featuring heavy operating conditions, Spiral wound gaskets are manufactured by spirally winding a V-shaped metal strip and a strip of non-metallic filler material. The metal strip holds the filler, providing the gasket with mechanical resistance and resilience. Spiral wound gaskets can be reinforced by an outer centering ring and/or inner retaining ring. The outer centering ring controls the compression and holds the gasket centrally within the bolt circle. The inner retaining ring increases the axial rigidity and resilience of the gasket. Spiral wound gaskets should always be in contact with the flange and should not protrude into the pipe or project from the flange.

Application

Spiral wound gaskets can be used for sealing flange joints, manhole and handhold covers, tube covers, boilers, heat exchangers, pressure vessels, pumps, compressors and valves; in industries such as petrochemical, pharmaceutical, shipbuilding, and food processing, in power industries and nuclear power stations. They are ideal for steam, oil, liquids, gases, acids, alkalines, various organic mediums and solvents.

The Material

1. Metal strap

A. made of 08F£¬0Cr13, 0Cr18Ni19Ti, 0Cr18Ni9Ti, 00Cr18Ni10, 0Cr18Ni12Mo2Ti, 00Cr17Ni14Mo2 cold-rolled steel strap with a thickness of 0.15mm~0.25mm or decided by the supplier and acquirer.

B. the metal strap should be pre-molding V-shaped or W-shaped narrow strap with smooth and clean surface, without any defects, such as roughness, cracks, scratches, drop pits or rusty spot, etc.

C. Hardness value of the stainless steel HV¡Ü200

2. Non-metal strap

A. the non-metal packing material is specially-made asbestos strap, flexible graphite strap, PTFE strap, non-asbestos fiber strap and isinglass strap with a thickness of 0.3-1.0mm.

B. loss of weight on ignition of specially-made asbestos should be ¡Ü25%.

C. chlorine ion content of non-metal strap should be ¡Ü100PPM.

D. the recommended temperature and pressure of various medium and different metal straps.

Table1

|

media material |

asbestos |

graphite |

non-asbestos |

PTFE |

|

Water-type media |

600¡æ£¬CL 2500 |

550¡æ£¬CL 1500 |

350¡æ£¬CL 1500 |

-200-260¡æ£¬ |

|

oil-type media |

500¡æ£¬CL 1500 |

550¡æ£¬CL 600 |

350¡æ£¬CL 600 |

-200-260¡æ£¬ |

|

gas-type media |

400¡æ£¬CL 600 |

550¡æ£¬CL 400 |

350¡æ£¬CL 400 |

200-260¡æ£¬ |

Note: used with non-oxygenization media, graphite can reach 800¡æ.

¡¡

Table 2

|

materials |

temperature ¡æ |

maximum work pressure |

applied media |

compression ratio |

resilience ratio % |

Stress relaxation force % |

|

Expansion graphite |

-220--550 |

250 BAR |

corrosion media |

18--30 |

¡Ý17 |

¡Ü18 |

|

specially-made asbestos strap |

-200---600 |

|

|

18--30 |

¡Ý19 |

¡Ü28 |

|

PTFE |

-200-- 250 |

100 BAR |

corrosion media |

18--30 |

¡Ý15 |

¡Ü13 |

|

Non-asbestos materials |

-100--250 |

100 BAR |

general air sealing |

18--30 |

¡Ý19 |

¡Ü28 |

|

isinglass |

-150--800 |

100 BAR |

special high temperature |

18--30 |

3) Strengthening ring. Unless specially agreed, the internal strengthening material should be the same with that of metal strap, and the materials of external strengthening ring should be A3 steel and have received anticorrosive treatment.

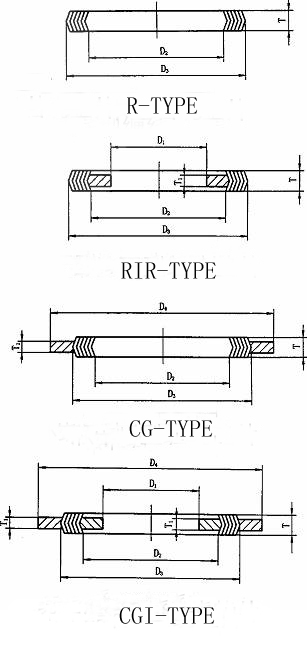

The main style of spiral wound gasket

|

|

Spiral Wound Gasket Without Inner and Outer Ring£¨R Style£© |

|

Spiral Wound Gasket With Inner Ring£¨RIR Style£© |

|

|

Spiral Wound Gasket With Outer Ring£¨CG Style£© |

|

|

Spiral Wound Gasket With Inner & Outer Ring£¨CGI Style£© |

The material & configuration of spiral wound gasket

|

Winding Hoop &Inner Or Outer Ring |

Filler |

Normal Thickness(mm) |

||||

|

Material |

Code |

Material |

Code |

Temperature(¡æ) |

V Shape/Ring |

|

|

Carbon Steel |

CS |

Asbestos |

ASB |

500 |

3.2/2.0 ¡¡ 4.5/3.0 |

4.8/3.0 5.5/4.0 7.5/5.0 |

|

Stainless Steel |

304(L)¡¢316(L) |

Graphite |

FG |

650 |

||

|

Monnel |

Mon |

PTFE |

PTFE |

250 |

||

|

Nickel£¬Titanium |

Ni,Ti |

Mica |

MICA |

950 |

||

|

Inconnel |

INC |

Ceramic |

CER |

1000 |

||

|

Hastelly c276£¬zirconium |

HAST,ZIRC |

Non-asbestos |

NAF |

300 |

||

Main Specification

|

Filler |

Temperature |

Pressure |

|

Graphite |

-200¡æ~+550¡æ |

250MPa |

|

Asbestos |

-150¡æ~+450¡æ |

100MPa |

|

PTFE |

-200¡æ~+260¡æ |

100MPa |

The style of flange and suitable spiral wound gasket style

|

¡¡ |

Flange |

Suitable Shape of Gasket |

|

FF Flange |

CG |

|

|

CGI |

||

|

RF Flange |

CG |

|

|

CGI |

||

|

FM Flange |

R |

|

|

RIR |

||

|

G Flange |

R |

|

|

RIR |

||

|

T Flange |

R |

|

|

RIR |

Terence of spiral wound gasket

| ¡¡ |

DIN (mm) |

ANSI B16.5 |

API 605 |

Terence(mm) |

|

Inner Diameter of Inner Ring/Inner Diameter of Gasket |

<=600 |

<=24" |

>=26" and <=34" |

¡À0.5 |

|

>600 and <=800 |

>24" and <=34" |

>=36" and <=60" |

¡À0.9 |

|

|

>800 and <=1600 |

>34" and <=60" |

¡¡ |

¡À1.3 |

|

|

>1600 |

>60" |

¡¡ |

¡À1.6 |

|

|

Outer Diameter of Gasket |

<=600 |

<=24" |

<=24" |

¡À0.9 |

|

>600 and <=160000 |

>24" and <=60" |

>24" and <=60" |

¡À1.8 |

|

|

1600 |

>60" |

¡¡ |

¡À2.2 |

|

|

Diameter of Outer Ring |

¡¡ | ¡¡ |

>=1/2"and<=60" |

¡À0.9 |

|

<=600 |

<=24" |

¡¡ |

0-1.0 |

|

|

>600 and <=1000 |

>24" and <=34" |

¡¡ |

0-1.8 |

|

|

>1000 and <=1600 |

>34" and <=60" |

¡¡ |

0-2.2 |

We can also produce as standard of JIS,JPI or as request.

How to Order

|

R |

WL-G1200A |

|

RIR |

WL-G1200B |

|

CG |

WL-G1200C |

|

CGI |

WL-G1200D |