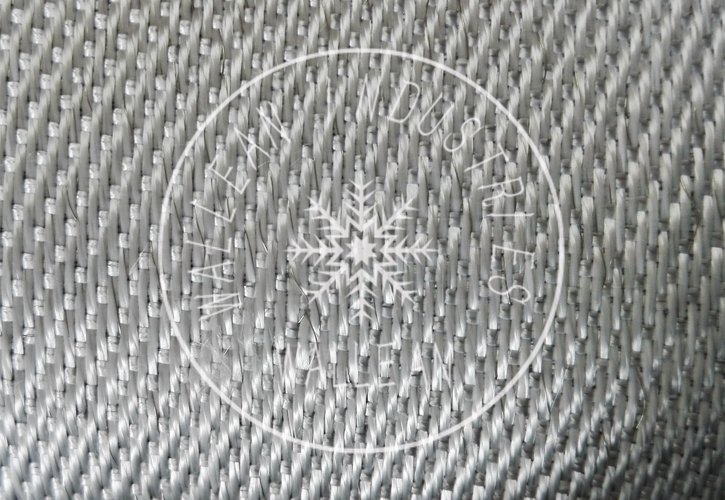

Stainless steeel wire insert fiberglass fabric

Description

- Stainless steel wire reinforced the fiberglass yarns

- Good rot and mildew resistance and tensile strength

- An alternative to asbestos based textiles

- A high-performance very high temperature fabric, used in almost all industries for heat protection

- Used at 700¡ãC continuous

Available with specialty coatings such as Acrylic, Aluminium foil/Mylar-aluminium, Dyeing, Heat treatment, Neoprene/Latex, Silicone rubber, PTFE(Teflon), PU, etc.

Common applications including

Heat shields, welding curtains, stress relieving, removable insulation covers, fire blankets, fire curtains, expansion joints,flue ducts and covers for fibrous insulation.

700¡ãC continuous rating, high insulation value & excellent personnel protection

Specification

|

700¡ãC: Stainless Steel Wire Insert Filament Fiberglass Fabric |

||||||

|

Part number |

US Code |

Thickness(mm) |

Weight(g/m2) |

Width(m) |

Length(m) |

Weave |

|

WFF102S |

7628 |

0.2 |

205 |

1.0-1.27 |

100 |

Plain |

|

WFF1041S |

3732 |

0.4 |

430 |

1.0-2.0 |

50 |

Satin |

|

WFF106S |

FW600 |

0.6 |

600 |

1.0-2.0 |

50 |

D-Plain |

|

WFF1062S |

666 |

0.6 |

660 |

1.0-2.0 |

50 |

Satin |

|

WFF108S |

3784 |

0.8 |

880 |

1.0-2.0 |

50 |

Satin |

|

WFF113S |

3786 |

1.3 |

1300 |

1.0-2.0 |

50 |

Satin |

|

WFF117S |

3788 |

1.7 |

1700 |

1.0-2.0 |

50 |

Satin |

|

700¡ãC: Stainless Steel Wire Insert Texturized Fiberglass Fabric |

||||||||

|

Part number |

WFF208S |

WFF210S |

WFF215S |

WFF220S |

WFF225S |

WFF230S |

||

|

Weave |

Plain |

Plain |

Plain |

Plain |

Plain |

Plain |

||

|

Yarn (tex) |

Warp |

480 |

480 |

1000 |

1720 |

2000 |

3000 |

|

|

Weft |

480 |

860 |

1000 |

1000 |

2000 |

3000 |

||

|

Thread count (ends per cm) |

Warp |

8.0¡À1.0 |

8.0¡À1.0 |

6.4¡À1.0 |

5.6¡À1.0 |

.0¡À0.5 |

4.8¡À0.5 |

|

|

Weft |

4.8¡À0.2 |

4.4¡À0.5 |

3.2¡À0.5 |

2.5¡À0.5 |

.8¡À0.2 |

1.7¡À0.2 |

||

|

Tensile strength |

Warp (N/50mm) |

1600 |

1800 |

4300 |

4300 |

5000 |

5900 |

|

|

Weft (N/200mm) |

1000 |

1100 |

2300 |

2300 |

2300 |

2400 |

||

|

Weight (g/ m2) |

650¡À50 |

800¡À60 |

1000¡À70 |

1300¡À85 |

1600¡À100 |

1800¡À110 |

||

|

Width (mm) |

1000mm-2000mm |

|||||||

|

Thickness (mm) |

0.8¡À0.08 |

1.0¡À0.10 |

1.5¡À0.15 |

2.0¡À0.2 |

2.5¡À0.25 |

3.0¡À0.30 |

||

|

Roll length (m) |

50¡À1 |

50¡À1 |

50¡À1 |

30¡À1 |

30¡À1 |

30¡À1 |

||

Fiberglass products are resistant to oils, solvents and most chemicals although contact with hydrofluoric acids, strong alkalis and live steam should be avoided.