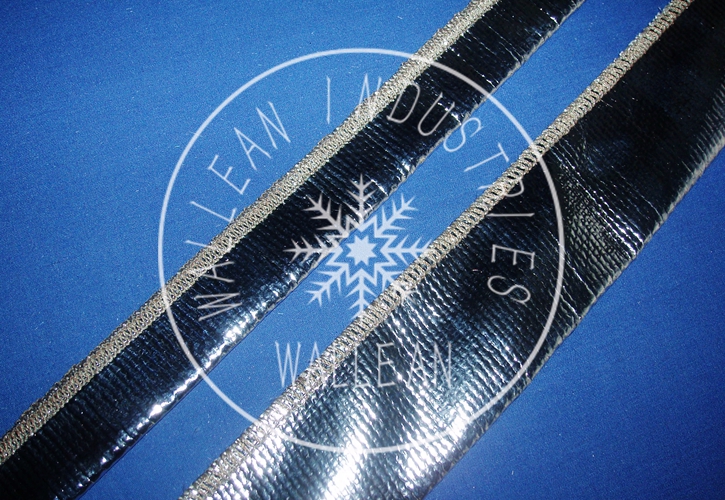

Alum glass sewn sleeve

Description

- Protection from intense radiant heat.

- Reflects more than 95% of the radiant heat that contacts its surface.

- Base fabric rated for continuous operation at 1000¡ãF / 537¡ãC.

- This sleeve is the perfect protection for cables and hoses when radiant heat from infrared sources such as super-hot metal slabs, proximity to liquid metal, open flame/plasma or engine exhaust manifolds is a concern.

Constructed from a high temperature base filament/texturized fiberglass fabric which is then coated with highly reflective polished aluminum. The aluminum foil coating melts at 1220¡ãF / 660¡ãC, however it does take some time for the aluminum foil to absorb enough heat to melt, thereby it can withstand short exposure to the higher temperatures. The basic fiberglass fabric is 1000¡ãF/537¡ãC, while adhesive will burn-off or vaporize at temperatures above 300¡ãF/148¡ãC.

The sleeve is fabricated from a roll fabric, and is sewn with a double lock-stitch seam utilizing hightemperature Kevlar thread. The resulting sleeve has a teardrop or tadpole profile when viewed on-end;the width of the sewn tail is typically 6mm.

Specification

|

1000¡ãF / 537¡ãC: Aluminum Foil/Mylar Film Coated Fiberglass Sewn Sleeve Radiant Heat Reflective Sleeve |

||||

|

Part number |

Inner Diameter (inch) |

Inner Diameter (mm) |

Wall thickness (mm) |

Roll Length (ft) |

|

WFF208A-TS06 |

1/4 |

6 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS12 |

1/2 |

12 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS16 |

5/8 |

16 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS25 |

1 |

25 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS28 |

1 1/8 |

28 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS38 |

1 1/2 |

38 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS41 |

1 5/8 |

41 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS51 |

2 |

51 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS54 |

2 1/8 |

54 |

0.8¡À0.1 |

3/12 |

|

WFF208A-TS63 |

2 1/2 |

63 |

0.8¡À0.1 |

3/12 |

Basic fabric can be available by WFF208A, WFF210A, WFF215A, WFF220A

Other sizes are available by customer¡¯s request.